For the 220kV Oil Immersed Power Transformer, we can produce capacity upto 240MVA. We use the best quality of raw material and advance design software to provide low noise, low losses, low partial discharge and high short-circuit impedance for power transformer.

Our power transformer are widely used in national grid, city grid, rural grid, power plant, industrial and mining enterprise, and petrochemical industry.

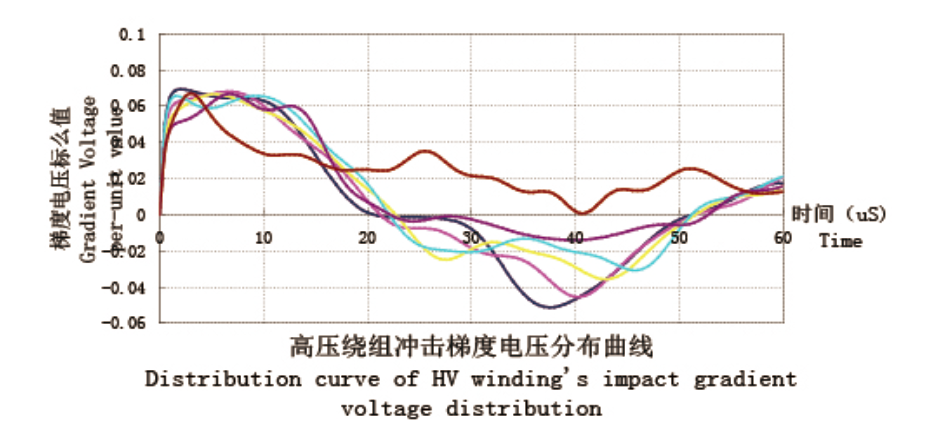

1. Potential distribution is effectively improved by application of software to calculate the impact and gradient potential distribution. The potential calculation is also done between various parts of the coil including between the coil and coil and earthing.

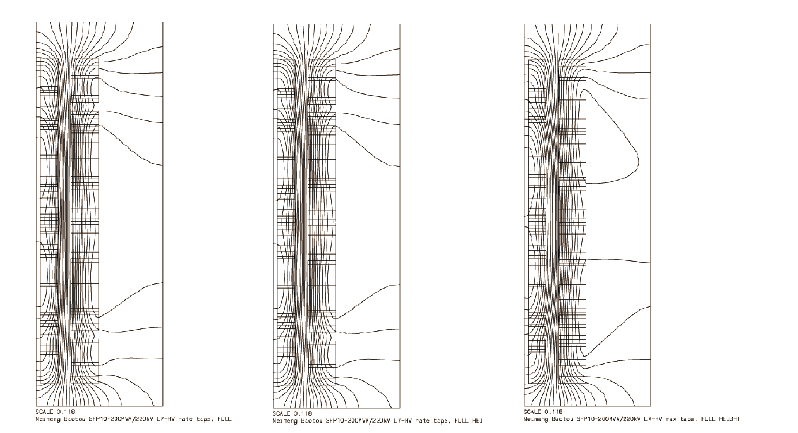

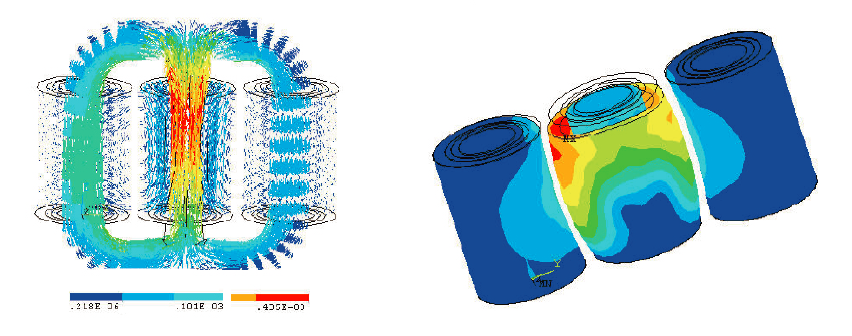

2. Low loss: Magnetic flux leakage calculation and corresponding measures to effectively reduce the stray loss, and in the meantime effectively prevent local overheating and lower temperature rise of winding hot spots. The electromagnetic optimizing design software is applied to optimize the core and winding design.

3. High resistance to short-circuit capacity: Apply transformer resistance to short-circuit capacity accounting software to design HV winding and LV winding. HV winding will be designed as central outlet, up and down parallel connection with axial oil path; the regulating winding will be designed as central outlet in the middle of HV winding with up and down parallel connection to improve transformer short-circuit resistance.

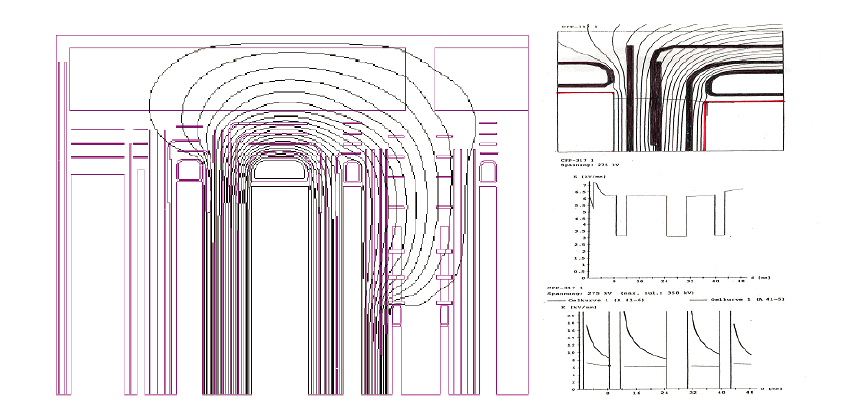

4. Low partial discharge, extend Transformer Service life.

(1) Analyze calculation of electric field to improve the electric field concentrated region.

(2) The way of vacuum oil filling will effectively prevent the formation of air bubbles inside the transformer and insulation parts to reduce partial discharge.

5. Low noise: Lower the noise level by choosing high quality steel core material; right flux density and the self-vibration frequency of the core; application of high resistance to short-circuit of the body structure; and improving the connection method of tank and active part.

6. Low temperature rise: Apply reasonable oil flow distribution structure by calculation of oil flow distribution; reduce the winding hot spot temperature rise and the average temperature rise in order to increase overload capacity of each part, extend the life of transformer.

Contact: James Wang

Phone: 13588429173

E-mail: James@qre.com.cn

Whatsapp:13588429173

Add: No.168, Hangqian Road, Guali Town, Xiaoshan District, 311243, Hangzhou City, China.